Inclination Sensors: Pointing Solar Power in the Right Direction

5504 °C surface temperature, 4.57 billion years old, a hundred times larger than the earth. As the central star in the sky, the sun releases 20,000 times the energy required by mankind per second. Solar energy is therefore also seen as one of the most important answers to the question of profitable renewable energies. Pepperl+Fuchs offers various products for this purpose, such as the F199 tilt sensor for precise measurement of tilt angles and position measurements. In this blog post, we explain what CSP (Concentrated Solar Power) plants are and how tilt sensors from Pepperl+Fuchs make them even more productive …

What Are CSP Plants?

CSP plants generate electricity by using mirrors to focus the sun’s rays on a small surface containing a carrier medium (e.g., thermal oil). Solar rays heat the carrier medium to produce steam, which drives the plant’s turbines or engines to produce electricity. Thermal energy is stored at the plant and can be used to produce electricity anytime. Parabolic troughs and power towers are the most common technologies used in CSP plants.

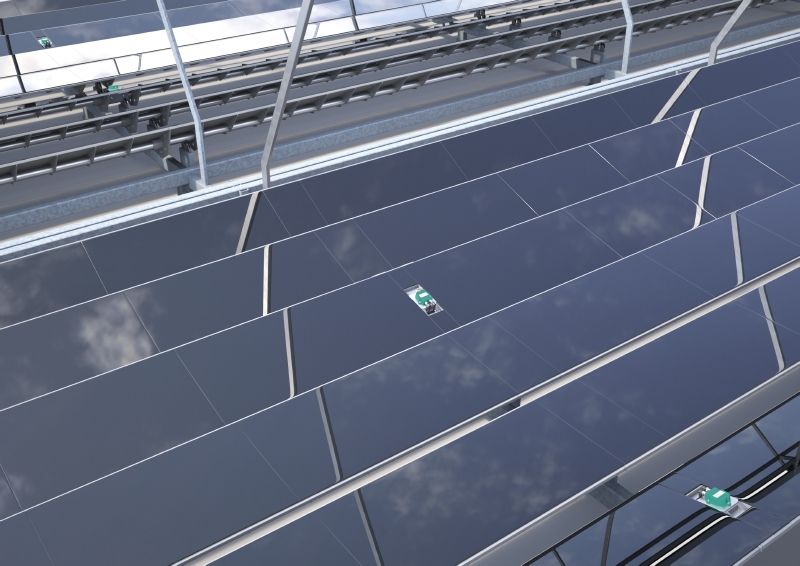

Parabolic Troughs

Parabolic troughs are used in 95 % of commercial solar power plants worldwide. These consist of a series of curved, parabola-shaped reflectors with mirror coating. The mirrors focus sunlight on a receiver tube. In the receiver tube, a heat transfer fluid (e.g., molten salt), is heated to between 150 °C and 380 °C to generate electricity in a conventional steam generator.

Power Towers

Thousands of solar tracking mirrors (heliostats) reflect sunlight onto a central receiver at the top of a tall tower. The concentrated sunlight increases the temperature of the heat transfer fluid located inside the receiver to about 600 °C to create steam that powers a conventional turbine. The turbine is then able to produce electricity.

It’s the Angle That Counts

In order for thousands of mirrors in a CSP plant to concentrate the maximum solar irradiation on an absorber, sensors are needed to finely tune the angular position of the reflector mirrors. The importance of high-precision sensors, such as the F199 or F99 tilt sensor from Pepperl+Fuchs, is demonstrated by the low efficiency of CSP plants due to inaccurate angle settings. Under accurate direct irradiation, the net value of electricity generated is around 16%.

The supposedly low output is influenced by five loss factors:

13 % cosine loss due to uniaxial tracking.

21 % loss due to fouling, tracking errors, etc.

10 % loss due to heat radiation at the absorber and field loss

38 % Loss due to capacitors

2 % loss due to self-consumption in solar tracking systems

With the high precision tilt sensor F199 the shown power loss can be reduced to a minimum. This is made possible by its high-precision accuracy of ±0.15° – over the entire measuring range from 0 to 360° across both axes. In this way, cosine loss, i.e. loss due to obliquely incident solar radiation, as well as tracking errors can be minimized and the energy output maximized.

High precision and a rugged design make the F199 and F99 the ideal inclination sensors for CSP plants. CSP plants are commonly installed in desert-like environments, so installed sensors must withstand extreme conditions such as sandstorms, drastic temperature changes, and harsh cleaning processes. The -45 °C to +85 °C extended temperature range of the F199 enables use in even the hottest regions of the world. The F199 has a corrosion-resistant aluminum housing, so maintenance is kept to a minimum, and the encapsulated electronics are IP68/69 protected.

CSP plants can make a significant contribution to energy production around the globe. If the planned investments in today’s CSP plants are implemented, around 25 % of the eco-power generated worldwide could come from solar thermal energy by 2050. With the right sensor technology, efficient energy production in CSP plants is possible both now and in the future.

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.