Configuring the 7500 Series Purge and Pressurization System

The 7500 series is a type Z/Ex pzc purge and pressurization system that enables non-rated electrical equipment to be used in hazardous areas. The 7500 series is a certified system for UL Class I and II/Div. 2 as well as for Zone 2/22 hazardous locations. A complete 7500 purge and pressurization system requires a control unit, a manifold valve, and a vent. It can be configured as a manual or fully automatic system. This blog article shows you how to configure the 7500 series purge and pressurization system components, i.e. control unit, manifold valve, and vent.

Control Unit

The 7500 series control unit is universal AC/DC. The control unit has a backlit LCD display that can be adjusted for vertical or horizontal orientation. The user can select one of the 5 pre-programmed operating options. Programs 1 to 4 are for hazardous gas applications and program 5 is for hazardous dust applications. Depending on the application, the user can select a program. A touchscreen display makes it easy to select a program and monitor pressure. In addition to the touchscreen display, the LED indicators allow the user to monitor the system condition.

Control unit 7500 series

The LED colors indicate the following states:

Encl: Green—contact (K1) switched (release signal for voltage in the enclosure)

Aux: Red—contact (K2) switched (alarm/control contacts)

Press SV: Blue—safe pressure reaches P1 (minimum enclosure pressure)

Press SV: Red—solenoid manifold switched (purging/pressure compensation)

The 7500-01-AA-STD-UNV-PNO control unit is available only in panel mount. If an external mount is preferred, the 7500-MTD-BX** configuration with the manual valve should be considered.

Manifold Valve

Depending on the manifold valve selection, the 7500 series can be configured as a manual or fully automatic system.

The manual manifold valve model 7500-MAN-MV-01 houses the ball valve for purging and a needle valve for pressurizing the enclosure. It does not require power like the digital manifold valve. If the manual manifold valve is preferred, we offer the 7500-01-AA-STD-UNV-PNO control unit and the 7500-MAN-MV-01 manifold valve in a compact 7500-MTD-** housing. The 7500-MTD-** is configured based on panel or external mounting and square or rectangular housing.

7500 external mounting option is only available with the 7500-MAN-MV-01 manual manifold valve in the 7500-MTD-BX** rectangular or square housing.

Manual manifold 7500-MAN-**

The 7500 control unit with manual manifold is available for either panel or external mounting in the compact 7500-MTD-** housing.

The digital manifold valve 5500-MAN-** is utilized with the 7500-01-AA-STD-UNV-PNO or the 5500-** control unit for a fully automatic system. The 5500-MAN-** combines a solenoid valve for purging and a needle valve for pressurization in one manifold. The supply inlet connects to the inlet of the manifold. Once the valve is energized, the solenoid valve opens, sending the protective gas supply to the enclosure from the manifold outlet. If needed, adjustments to the flow can be made by adjusting the needle valve.

The configuration of the 5500-MAN** manifold valve depends on both the voltage and approval required for the application:

- Approvals:

- CDUL: UL & CSA

- EX01: ATEX & IECEX

- Voltage:

- 24 VDC

- 120 VAC

- 230 VAC

For example: The digital manifold valve 5500-MAN-CDUL-24 VDC is for an application that requires a 24 VDC manifold for a UL Class I /Div. 1 application.

Digital manifold valve 5500-MAN-**

Vent

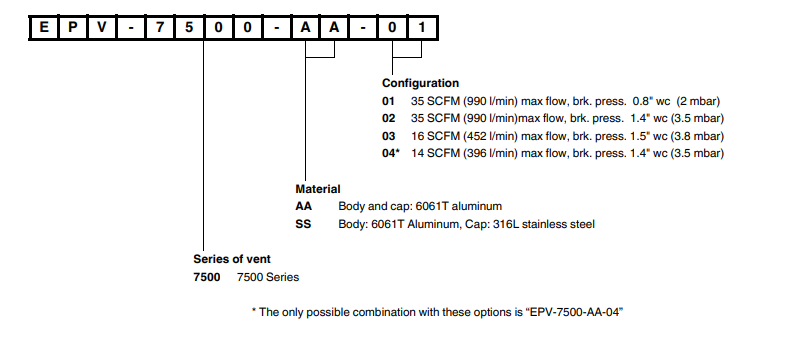

The EPV-7500-** vent is required for both automatic and manual configuration. The configuration options for the vent are provided in the type code below:

The vent is configured based on the vent cap material and the charts illustrating the vent flow versus the enclosure pressure.

These charts are available both on the datasheet and in the manual.

The vent material options are stainless steel (SS) or aluminum (AA):

EPV-7500-AA-** Body and cap made of 6061T6 aluminum

- The aluminum vent is intended to be mounted on the outside of the enclosure.

EPV-7500-SS-** Body made of 6061T6 aluminum, cap made of AISI 316 (1.4401) stainless steel

- This vent type has an aluminum body that is mounted on the inside of the enclosure with a stainless steel cap on the outside.

The model EPV-7500-**-01 is the most commonly used vent. It is good for large and small enclosures.

EPV-7500 vent

Subscribe to our newsletter and receive regular news and interesting facts from the world of automation.